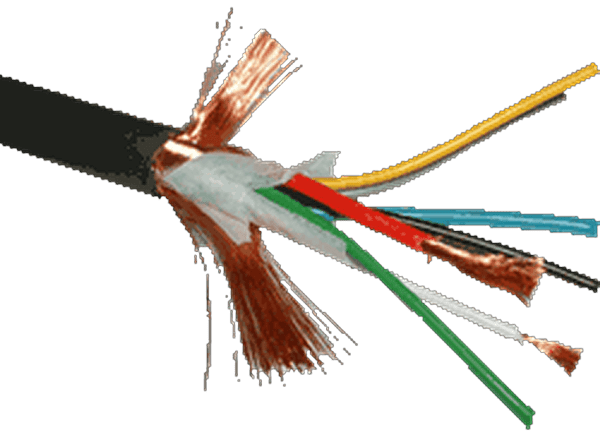

Gotham "Star-Quad" cables are the most advanced microphone cables presently available. We have combined an ultraflexible PVC-jacket, low capacitive PE insulation, "double Reussen shielding" and quad (4-conductor) construction for a truly professional cable at an affordable price. The "Star-Quad" concept is known and recommended where the RF-rejection is the most important factor and where very long cable runs are needed. As we use each 2 conductors for low and high signal, we reduce the signal loss by 50% and due to the offset of the incoming RF-signal by the way the 4 conductors are twisted, the RF-rejection is over 130dB (25 kHz). The exclusive double shielding does its part of these features as well.

Now we have furter added another protection feature to the construction for ultimative shielding and/or

2 Channels (Stereo) balanced useage!

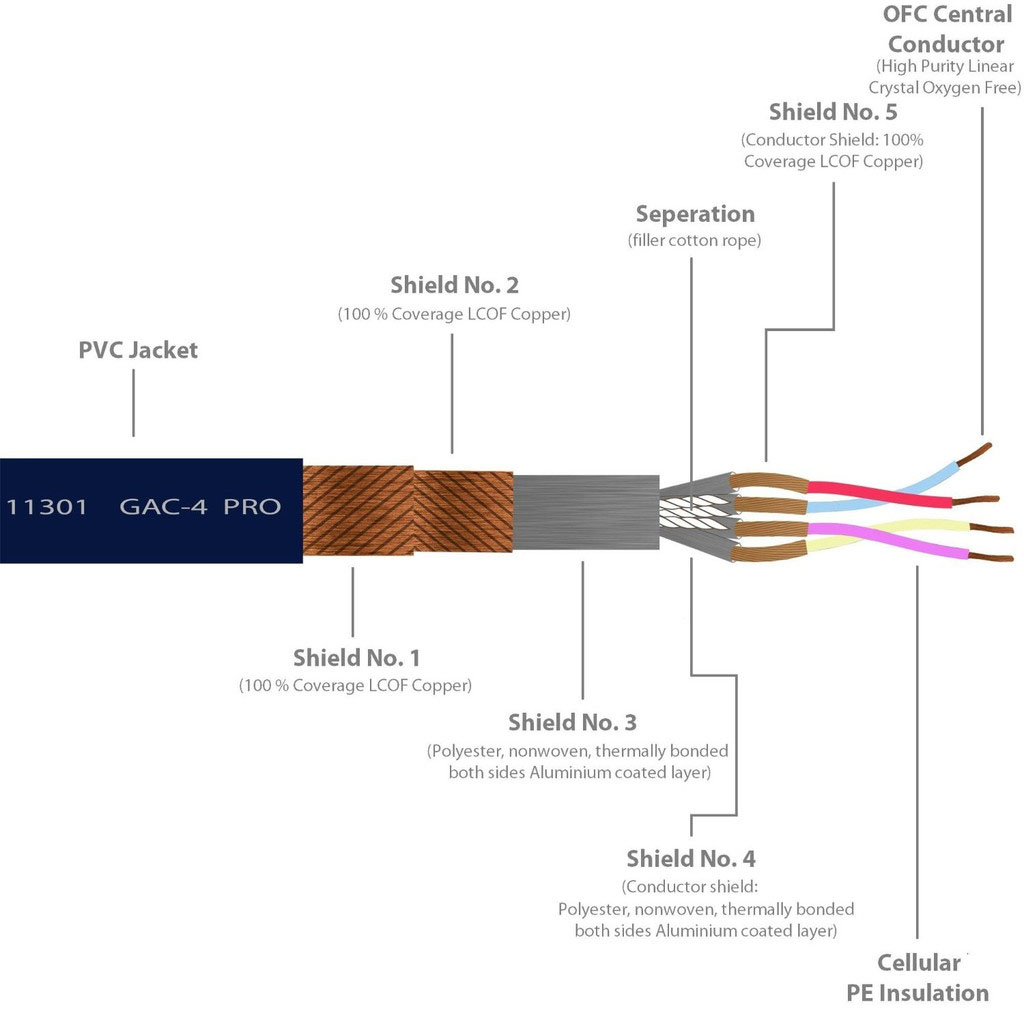

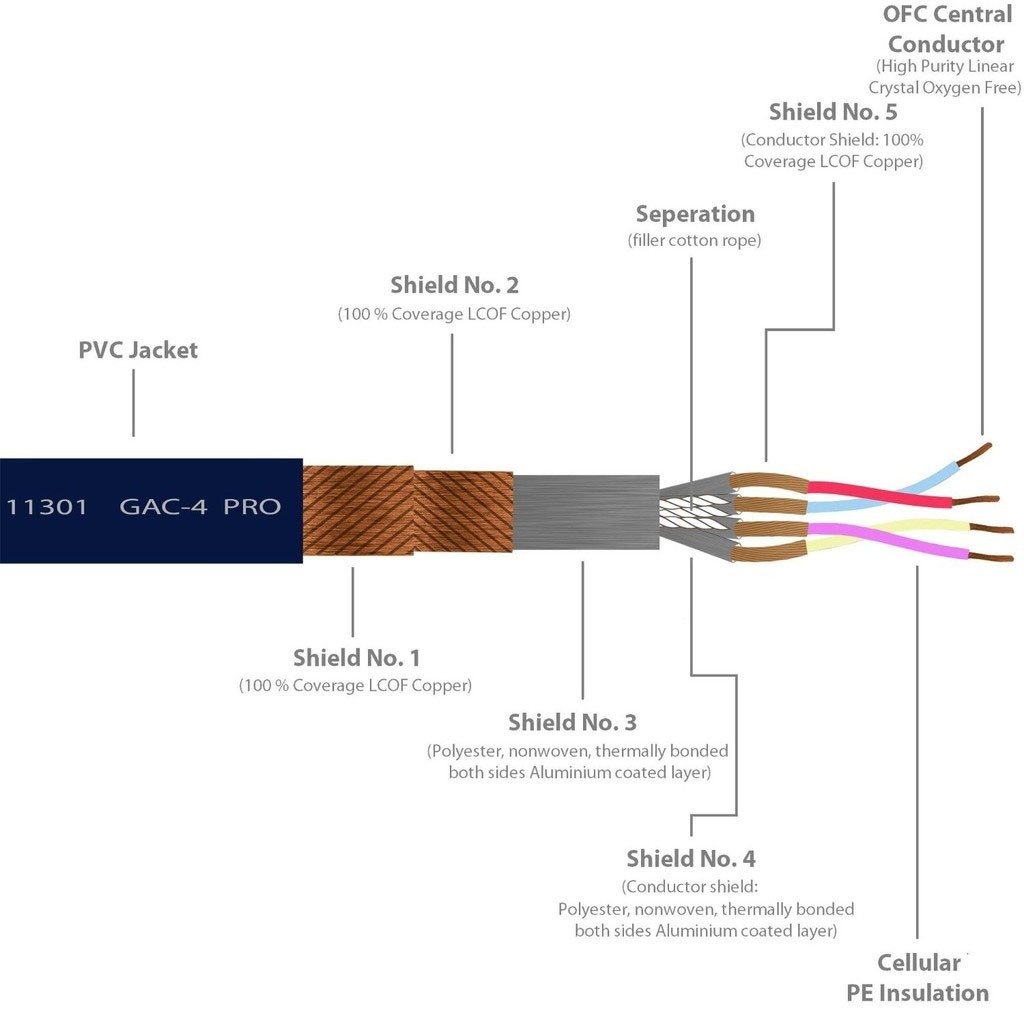

11301 is a starquad balanced single channel 5 times shielded audio cable! Ultraflexible professional audio cable for microphones. 'Double Reussen shield', velvet matte non-light reflecting PVC-jacket material. A unique construction new invented by Gotham design.

Each of the 4 conductor is shielded with a lap shield 100% covering copper wires (7) (Reussen shield) plus a conductive separation layer (6) (Aluminium coated Poyester ). This conductor is twised in starshape around conductor nr 2/3/4 and turn ist holded in place with another aluminium coated layer (4), followed by Gotham's unique double Reussen shield. This cable is absolutely uncompromised to acheive maximum shielding possible while the flexibility and durability is still very good and the cable can be used in mobile applications as well.

One can also use the cable as a 2 channel balanced cable giving still perfect crosstalk and shielding of each channel!

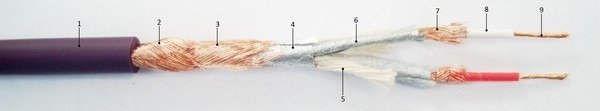

Construction: |

||

| 1 = Jacket: | PVC, Ø 8.80mm ultramarine blue RAL5013 | |

| 2 = Shield No. 1. | Bare copper wires (0.10 mm) 100% coverage | |

| 3 = Shield No. 2. | Bare copper wires (0.10 mm) 100% coverage | |

| 4 = Layer | Polyester nonwoven thermally bonded, both sides aluminium coated |

|

| 5 = Seperation | Filler material viscose | |

| 6 = conductor shield layer | Polyester nonwoven thermally bonded, both sides aluminium coated |

|

| 7 = conductor copper shield | Bare copper wires (0.10 mm) 100% coverage | |

| 8 = Insulation | Cellular PE, Ø 2.00mm, 4 diffrent colors, red,white,ivory/pink | |

| 9 = Conductor | Stranded bare LCOF copper wires 64 x 0.10mm (4x) (0.50mm2) 64x38AWG = 20 AWG (0.32mm²) |

|

Technical Datas: |

||

| Conductor resistance: | max 39 ohm/km | |

| Shielding resistance: | < 28 Ohm/km | |

| Copper weight: | per 100m | 7.010 Kg/km Higher grade LCOF Copper |

| Capacitance: | cond/cond: | max. 50 nF/km |

| cond/shield: | max. 103 nF/km | |

| Side circuit capacitance: | cond/cond: | max. 55 nF/km |

| Side circuit capacitance: | Quad system | max. 135 nF/km |

| Noise attenuation: | 130 db (> wiring) | |

| Test voltage: | cond/cond: | 500 veff |

| cond/shield: | 2000 veff | |

| Operating voltage: | high voltage | |

| Temperature range: | flexi-installed: | -5° to +50° C |

| fix-installed: | -30° to +70° C | |

-shielded,-high-flex-pvc-up-to-240vac.jpg?width=152&height=190&store=vi&image-type=small_image)